WTEYA GROUP

Recirculating Leachate

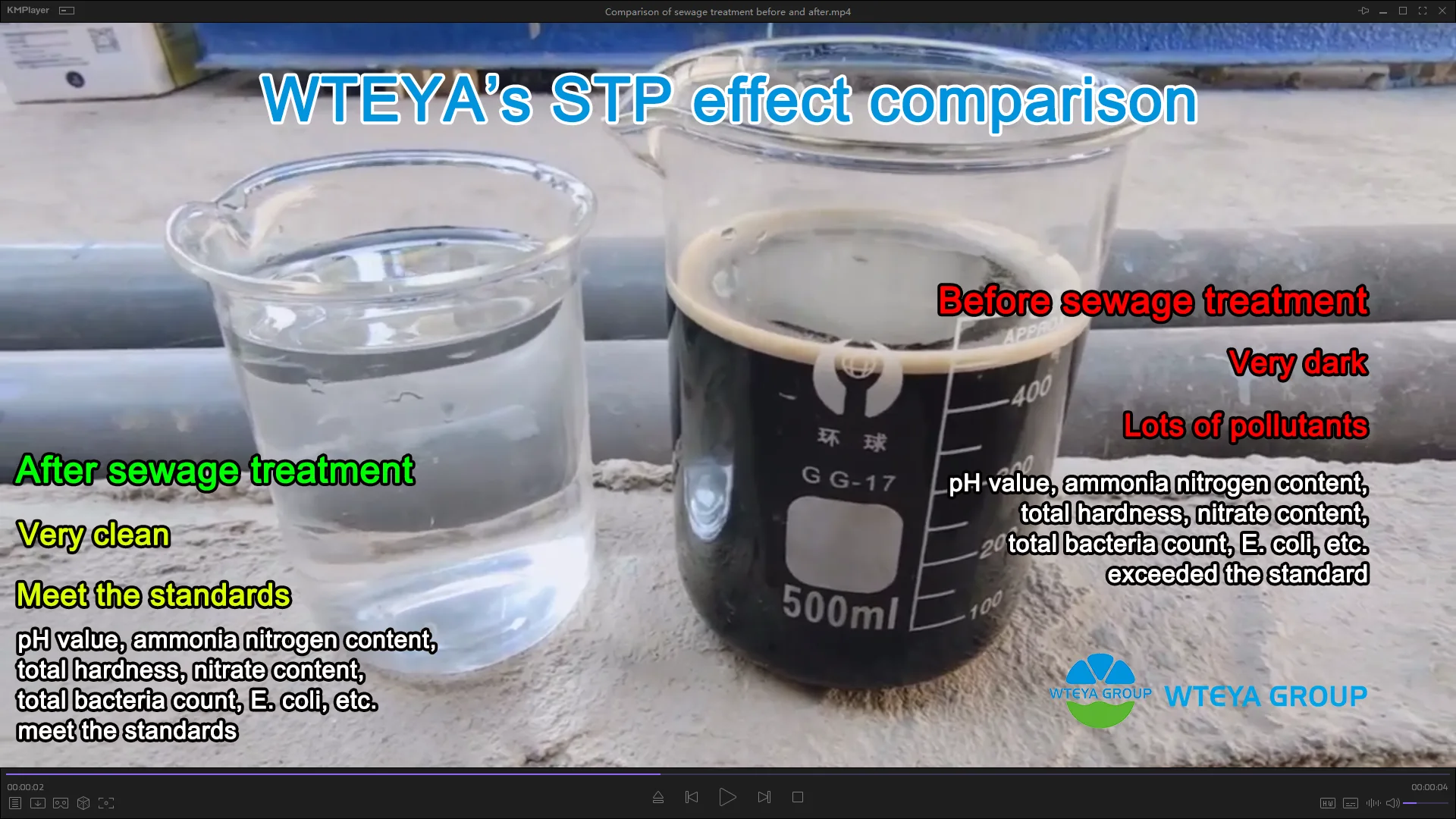

Reuse Of Wastewater

One of our most advanced solutions is to use the landfill itself to absorb the leachate. Recirculating the leachate through the landfill has the added benefit of increasing the production of landfill gas (LFG), which can then be used to fuel a leachate evaporator or a landfill gas to energy system.

Water recycling

The treated water can meet the reuse standards and be used for irrigation, industrial cooling or other purposes.

Online monitoring system

Amet minim mollit non deserunt ullamco est sit aliua dolor do amet sint.

100% Customer Satisfaction

Free design plan! High degree of automation, high processing efficiency and strong applicability.

WHAT WE DO

Our Leachate Treatment System Solutions

Will Do More For You!

Our leachate solutions are compact, modular and pre-packaged to minimize on-site installation costs. We partner with the best for biological treatment—if required—and your local contractors for integration. We can help you understand your options, costs, risks, and how to meet regulatory requirements including options for zero liquid discharge.

Real-Time +

Remote Monitoring System

Continuously tracks and analyzes leachate volume, flow rate and chemical composition. It is able to identify harmful substances, measure pH, determine biological and chemical oxygen demand (BOD and COD) and specific pollutants.

Trigger Alerts +

Take Control

Create custom thresholds and set alerts to notify you of issues discovered in real time, as well as issues discovered by analyzing historical data sets. Create thresholds that trigger changes to actions and deliveries.

Optimize Operations +

Meet Emission Standards

Use advanced automation to improve the efficiency and effectiveness of landfill leachate detection + management operations. Effectively reduce operating costs, improve work efficiency, and produce stable water that meets standards.

Characteristics Of Leachate Water

Leachate Treatment Options

At many municipal landfills, household waste is deposited together with different kinds of industrial waste. This means that the composition of leachates from landfills can vary widely depending on the waste deposited and the age of the landfill.

Conventional Treatment Solution:

Conventional Treatment Solution:

In some cases, the best solution is to reduce the volume of leachate using a leachate evaporator. Powered by landfill gas, the evaporator heats the leachate, drives off the water vapor, and leaves behind sludge and solids that can be safely disposed of on the active working surface of the landfill. Evaporators can be used alone or in conjunction with other technologies as part of a leachate management system. Zero liquid discharge of leachate wastewater can be achieved.

Full Quantization Processing Solution:

Full Quantization Processing Solution:

In some cases, the best solution is to reduce the volume of leachate using a leachate evaporator. Powered by landfill gas, the evaporator heats the leachate, drives off the water vapor, and leaves behind sludge and solids that can be safely disposed of on the active working surface of the landfill. Evaporators can be used alone or in conjunction with other technologies as part of a leachate management system. Zero liquid discharge of leachate wastewater can be achieved.

Emergency Treatment Solution:

Emergency Treatment Solution:

This treatment process equipment has the advantages of low energy consumption, strong mobility, flexibility, short construction period, small footprint, ready for use, easy operation and maintenance, strong adaptability, etc. The interception rate of organic pollutants, monovalent salts, divalent salts, etc. reaches more than 99%, and the company can efficiently remove organic matter and ammonia nitrogen in deionized water.

Project & Implementation

The company "WTEYA" designs and manufactures a range of equipment for leachate treatment. With the help of evaporation equipment, the problem of zero-discharge treatment of leachate can be effectively solved.

The introduction of evaporation equipment in landfills or incineration plants helps to save resources and reduce costs: a "zero-pollution" green solution, resource recycling, and less money required for wastewater treatment. We offer various models of evaporation equipment, reverse osmosis equipment, ultrafiltration equipment, filtration equipment, etc. If necessary, we can tailor it for you.

Landfill Leachate Management System

From R&D, engineering design to equipment supply, commissioning, startup and performance testing project execution, WTEYA is your trusted project development partner, supporting OEM and ODM customization, providing high-quality leachate treatment and evaporation systems for all landfills and incineration plants.

Pretreatment

system

Such as grids, screens intercepting solid impurities.

Primary

treatment system

Such as regulating tanks, regulating flow.

Secondary

treatment system

Such as biological treatment, removing organic matter.

Tertiary treatment

system

Such as advanced oxidation, membrane filtration.

Intelligent control

systems

Intelligent control systems, remote monitoring systems.

Other

auxiliary devices

Blower device, dosing station device, etc.

About WTEYA

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Founded in

Professional staff

Factory area

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.

Middle East Agent

Saudi Arabia Exhibition

Iraqi Clients

Project Site Inspection

Jordanian Clients

Indonesia Agent

Middle Eastern Clients

Shanghai Exhibition

Vietnam Exhibition

Agent Learning

French Clients

Get a free quote!

Let professionals help you choose

Our Customers And Services