WTEYA Full-quantitative Electroplating Wastewater Treatment Solution

Release Time:

2025-12-11 10:00

⚡ WTEYA Full-quantitative Electroplating Wastewater Treatment Solution | Solve Heavy Metal Exceedance Problems, Recycle Resources, and Achieve Sustainable Production!

The electroplating industry is faced with multiple challenges, such as high pressure in treating heavy metal wastewater containing nickel, chromium, copper, etc., high operating costs, and severe resource waste. WTEYA provides a full-process solution from pretreatment to advanced purification and zero liquid discharge, which not only ensures stable compliance with discharge standards, but also enables the "full recovery" of valuable metals from wastewater.

🔬 Our Technical Approach:

✅ High-efficiency Pretreatment: Targeted decomplexation and neutralization precipitation to create optimal conditions for advanced treatment.

✅ Core Resource Recovery: Adopting special membrane separation, MVR evaporation concentration and electrolytic recovery technologies to achieve a heavy metal recovery rate of >99%, which can be directly reused in the production line.

✅ Ultimate Zero Liquid Discharge: The concentrated solution is subjected to forced circulation evaporation and crystallization to produce industrial-grade salt residue; the distilled water is reused in production to realize in-plant water resource recycling.

✅ Intelligent Control: A fully automated PLC system that monitors water quality and recovery efficiency in real time to ensure the efficient and stable operation of the system.

🏭 Why Choose WTEYA?

- Customized Design: Deeply understand electroplating processes and tailor solutions for different production lines such as rack plating, barrel plating, and continuous plating.

- Outstanding Benefits:

- Environmental Benefits: Completely eliminate the anxiety of discharge compliance.

- Economic Benefits: Recycled metals and water resources directly reduce production costs with a short investment payback period.

- Management Benefits: Automated operation greatly reduces the difficulty and cost of manual operation.

💪 WTEYA Strength Support:

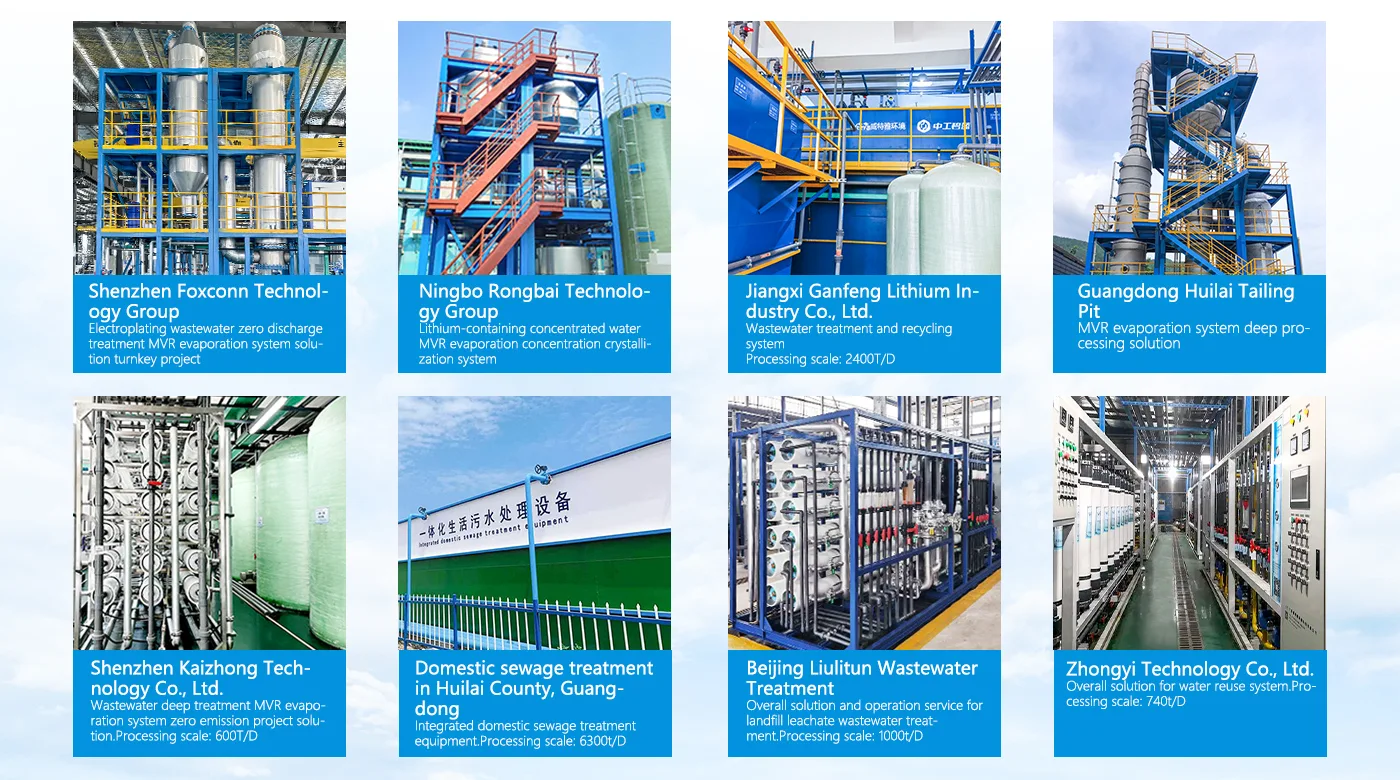

- 20 Years of Experience: Specializing in high-difficulty industrial wastewater treatment with mature and reliable technology.

- Complete Qualifications: Fully certified with CE, ISO, etc., ensuring worry-free project acceptance.

- Global Cases: Serving more than 2,000 customers worldwide with a large number of successful cases in electroplating parks and enterprises.

- One-stop Service: Provide full-cycle support including design, manufacturing, installation, commissioning and training.

🌍 Global Agent Recruitment is in Full Swing!

We sincerely invite environmental protection engineering companies and agents from all over the world to join us and jointly explore the 100-billion-level environmental protection market in the electroplating industry! We will provide comprehensive technical training, market support and profit margins.

📞 Get Solutions and Agent Information Now:

📱 WhatsApp: +86-1800 2840 855

✉ Email: info@wteya.com

🌐 Website: www.vteya.com

Related information

WTEYA provides a full-process solution from pretreatment to advanced purification and zero liquid discharge, which not only ensures stable compliance with discharge standards, but also enables the "full recovery" of valuable metals from wastewater.

WTEYA Full-quantitative Electroplating Wastewater Treatment Solution

WTEYA provides a full-process solution from pretreatment to advanced purification and zero liquid discharge, which not only ensures stable compliance with discharge standards, but also enables the "full recovery" of valuable metals from wastewater.

A Special Visit From Malaysia!

A Malaysian client brought a wastewater problem to WTEYA. We tailored a "Low-Temperature Evaporation Experimental Solution" for the client.

The WTEYA MVR (Mechanical Vapor Recompression) evaporation zero-discharge system offers the ultimate solution: it discharges no wastewater to the outside and recovers valuable water resources and by-products.

WTEYA Agents Visit Headquarters for Technical Training!

WTEYA Global Agents Technical Training Concludes Successfully | Empowering Partners to Create a New Chapter in the Industry!

Is Landfill Leachate Dark, Foul-Smelling, and Highly Toxic?

WTEYA's Leachate Treatment System Solution! High-efficiency biochemical treatment + advanced membrane filtration: COD and ammonia nitrogen are easily degraded, making stable compliance no longer difficult!