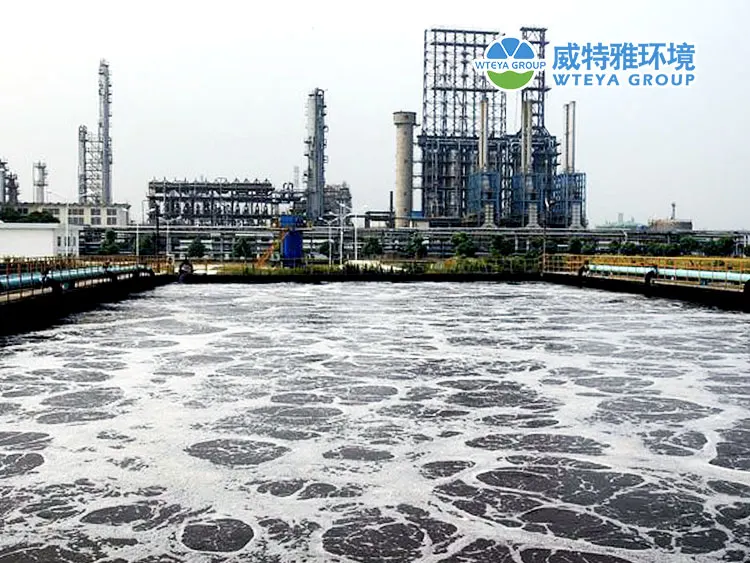

Coal chemical wastewater treatment

Release Time:

2024-07-10 15:57

What is coal chemical industry?

Coal chemical industry is an industrial process that uses coal as raw material, converts coal into gas, liquid, solid products or semi-products through chemical processing, and then further processes it into chemical and energy products to achieve comprehensive utilization of coal.

Traditional coal chemical industry mainly refers to the coking industry, calcium carbide industry, nitrogen fertilizer industry, and methanol industry. Modern coal chemical industry mainly refers to coal liquefaction, coal-to-olefins, coal-to-ethylene glycol, coal-to-natural gas, etc.

Whether it is traditional coal chemical industry or modern coal chemical industry, the coal processing process mainly includes: distillation (including coking and low-temperature distillation), gasification, liquefaction and synthetic chemicals, etc.

Do you know the upstream, midstream and downstream of the coal chemical wastewater treatment industry?

The upstream is mainly the coal chemical industry, including coal mining, coal processing, coal combustion, etc., as well as chemical raw materials and equipment manufacturing.

The midstream is mainly coal chemical wastewater treatment technology and equipment manufacturing, including sewage treatment technology, sewage treatment equipment, sewage treatment agents, etc.

The downstream is mainly coal chemical wastewater treatment services, including sewage treatment engineering design, construction, operation, etc.

WTEYA professionally provides one-stop coal chemical wastewater treatment solutions. Through the use of mature process technology, it ensures that the effluent water quality meets or exceeds the relevant standards, realizes the recycling of water resources, and reduces environmental pollution.

What are the problems in the coal chemical wastewater treatment industry?

1. Complexity and diversity: Coal chemical wastewater contains a variety of organic and inorganic pollutants, as well as high concentrations of chemicals, which leads to the complexity and diversity of the treatment process.

2. Technical challenges: Some pollutants in wastewater are resistant to traditional treatment methods, and new and efficient treatment technologies need to be continuously developed to ensure that the wastewater is thoroughly purified.

3. Resource recovery difficulty: It is challenging to recover useful substances from coal chemical wastewater, especially when the wastewater contains a variety of organic matter and impurities.

Coal chemical wastewater treatment requires different treatment technologies and methods according to different situations. If you want to improve the wastewater recovery rate, you can find WTEYA to obtain solutions.

Source of coal chemical wastewater

Washing wastewater generated during coal gas purification.

Water vapor formed by the precipitation of chemical water from the moisture in the coking coal and the coal material during thermal cracking, and condensed water formed by the primary condenser.

Recycling water vapor generated during the processing of by-products such as tar and crude benzene, among which the ammonia nitrogen-containing wastewater generated during the nitrogen evaporation process is the main source of pollution.

Pollutants in coal chemical wastewater

The pollutants in coal chemical wastewater are mainly phenol and ammonia, and there are more than 300 pollutants, such as tar, phenol, cyanide, sulfide, COD, etc. Coal chemical wastewater is not only highly toxic, but also difficult to treat. WTEYA's coal chemical wastewater treatment and zero-emission process technology can be used to achieve efficient treatment of wastewater and improve resource reuse rate.

Coal chemical wastewater treatment method

Coal chemical wastewater treatment refers to the process of treating wastewater containing organic and inorganic pollutants generated in the coal chemical production process to meet the national emission standards.

Coal chemical wastewater treatment methods mainly include three process flows: pretreatment, biochemical treatment, and deep treatment.

Pretreatment:

Mainly includes oil removal, phenol removal, nitrogen evaporation, SS removal (primary sedimentation tank, coagulation sedimentation tank) and toxic, harmful or difficult to degrade organic matter (desulfurization, cyanide destruction, advanced oxidation pretreatment, etc.).

Biochemical treatment:

Biochemical treatment mainly includes A/O, A2/O, SBR, UASB, etc. or some new processes. In each process, the reactor design parameters and bacteria have a great influence on its treatment effect.

Deep treatment:

After biological treatment, some organic matter that cannot be degraded by organisms still remains in the wastewater, making it difficult for the COD or color of the wastewater to meet the standards, so subsequent treatment must be carried out. Generally, there are coagulation, adsorption, advanced oxidation, membrane technology, etc.

Front page of Cross

Next go-to page

Related information

WTEYA 2025 Shanghai International Water Exhibition has come to a successful conclusion!

Exploding Shanghai, returning with honors! WTEYA 2025 Shanghai International Water Exhibition has come to a successful conclusion! The collision of technology and crowds, grateful for every encounter, looking forward to the next hand in hand!

In the Middle East, where natural freshwater resources are extremely scarce, WTEYA Kuwait Water Treatment Plant is using advanced water treatment technology to convert seawater and wastewater into reusable water sources, providing strong support for the country's sustainable development strategy. In recent years, as climate change and population growth have intensified water resource pressure,

WTEYA | Happy Dragon Boat Festival: Inheriting Culture, Protecting the Future

WTEYA wishes everyone a happy Dragon Boat Festival, may happiness flow like clear water, and life be as fragrant as zongzi.

RO water treatment system helps you solve the problem of pure water resources

As the problem of water shortage becomes increasingly serious, how to efficiently obtain pure water has become the focus of attention in industries such as industry, medical care, and food. With its efficient filtration and stable water production capabilities, the RO water treatment system has become the preferred solution to solve the demand for pure water, providing enterprises with safe and reliable water resources.

Portable seawater desalination machine for ships, islands, coastal hotels, etc.

As global freshwater resources become increasingly scarce, portable desalination technology is becoming a reliable solution for ships, remote islands and coastal hotels. Recently, WTEYA launched a new generation of portable desalination systems. The equipment is small in size and low in energy consumption. It can quickly convert seawater into directly drinkable fresh water, providing convenience for users who lack a stable supply of fresh water.

MVR evaporator is the preferred solution for heavy metal sewage treatment

With increasingly stringent environmental regulations, Heavy metal sewage treatment has become an important issue in the industrial field. Among many treatment technologies, MVR evaporator has gradually become the industry's preferred solution due to its high efficiency, energy saving, stability and reliability.