1. Evaporation equipment: such as MVR evaporation equipment, forced circulation equipment, low-temperature evaporation equipment, and multi effect evaporation equipment.

Applied in which production process

Evaporation equipment is mainly used in the mining and metallurgical industry for wastewater treatment, optimization of hydrometallurgical processes, and resource recovery. Specific applications include.

- Wastewater treatment and zero discharge (ZLD)

High salt wastewater treatment: The wastewater generated during mining and metallurgical processes often contains high concentrations of inorganic salts and heavy metal ions, and direct discharge can cause serious environmental pollution. Evaporation equipment (such as multi effect evaporators, mechanical vapor re compression evaporators (MVR), etc.) can evaporate the moisture in wastewater to form concentrated liquid and distilled water. Concentrated liquid can be further solidified for treatment or resource utilization, while distilled water can be reused in the production process or discharged to meet standards, achieving the reduction and resource utilization of wastewater.

Acid and alkali wastewater treatment: For wastewater containing acid and alkali, evaporation equipment can effectively concentrate the acid and alkali components in the wastewater, facilitate subsequent neutralization treatment or acid and alkali regeneration and utilization, reduce the cost of purchasing new acid and alkali, and reduce waste discharge.

- Optimization of Hydrometallurgical Processes

Leaching solution concentration: In hydrometallurgy, in order to improve the efficiency of subsequent extraction, precipitation, or electrowinning processes, it is sometimes necessary to concentrate the leaching solution. The evaporation equipment can quickly and effectively concentrate valuable metal ions in the leaching solution, reducing the energy consumption and cost of subsequent treatment.

Solvent recovery: When using solvent extraction and other wet metallurgical processes, evaporation equipment can be used to recover and recycle solvents such as alcohols, amines, etc., reducing solvent consumption, lowering treatment costs, and minimizing environmental impact.

- Resource recycling and by-product processing

Byproduct salt crystallization: Some wet metallurgical processes produce salt containing byproducts, such as sulfates, chlorides, etc. Evaporation equipment can evaporate and crystallize these salt solutions to obtain pure salt products, achieving resource utilization.

Concentration and recovery of heavy metal salts: For wastewater or by-products containing heavy metal ions, evaporation equipment can concentrate the heavy metal salts in order to recover heavy metal resources through chemical precipitation, electrodeposition, and other methods, reduce environmental pollution risks, and increase economic benefits.

- Energy conservation and emission reduction

Waste heat utilization: Waste heat, low-temperature steam, or condensate generated during mining and metallurgical processes can serve as a heat source for evaporation equipment, achieving effective energy utilization and reducing overall energy consumption.

Reducing solid waste generation: Treating wastewater through evaporation equipment can greatly reduce the generation of solid waste (such as evaporation residue), lower the cost of solid waste disposal, and alleviate environmental pressure.

- Historical legacy of environmental restoration and governance

Waste liquid treatment: For high salt and heavy metal waste liquid left behind in abandoned mining areas, evaporation equipment can be used as one of the treatment technologies. Through evaporation and concentration of waste liquid, safe disposal or resource recovery of waste liquid can be achieved, helping to restore the mining environment.

Technical Principles

MVR evaporator equipment: The MVR evaporator reuses the energy of the secondary steam it generates, thereby reducing the demand for external energy. The working process of MVR is to compress the low-temperature steam through a compressor, increase the temperature and pressure, increase the enthalpy, and then enter the heat exchanger for condensation to fully utilize the latent heat of the steam. Except for start-up, the entire evaporation process does not require the generation of steam. The secondary steam coming out of the evaporator is compressed by the compressor, which increases pressure and temperature, enthalpy, and then sent to the heating chamber of the evaporator for use as heating steam, maintaining the boiling state of the material liquid.

Forced circulation evaporation equipment: The circulation of solution inside the equipment mainly relies on the forced flow generated by external force. The cycle speed can generally reach 1.5-3.5 meters per second. High heat transfer efficiency and production capacity. The raw material liquid is pumped from bottom to top by a circulating pump and flows inward and upward along the heating chamber tube. After entering the evaporation chamber, the mixture of steam and liquid foam separates, and the steam is discharged from the upper part. The fluid is blocked and falls down. It is sucked in by the circulation pump at the conical bottom and then enters the heating tube to continue circulation. It has a high heat transfer coefficient, resistance to salt precipitation, anti scaling, strong adaptability, and is easy to clean. Suitable for evaporative concentration in chemical, food, pharmaceutical, environmental engineering, waste liquid evaporation and recovery industries with scaling, crystallinity, thermal sensitivity (low temperature), high concentration, high viscosity, and insoluble solids.

Low temperature evaporation equipment: Low temperature evaporation refers to an evaporation process that operates at temperatures generally between 35-50 ℃. After the raw water bucket reaches the middle liquid level, the water pump operates to generate a vacuum, and the evaporator automatically receives water. The compressor operates to generate heat to heat the wastewater in the evaporation tank. Under vacuum, the wastewater temperature rises to around 30 ℃, and the wastewater begins to evaporate. Preheating is completed. The evaporation temperature is set to 35-40 ℃, and the compressor compresses the refrigerant to generate heat. While the water evaporates rapidly, the refrigerant absorbs heat and cools through the expansion valve after gasification. The vapor rises and liquefies with the cold liquid, entering the water storage tank. The refrigerant absorbs heat and compresses it through the compressor to heat up the wastewater. If there are bubbles rising during the evaporation process, the sensor will detect it and automatically add defoamer. After one cycle is completed, the concentrated solution will be discharged (the time of one cycle can be set). After one evaporation cycle is completed, the compression pump stops working, the pneumatic valve of the concentration liquid pipeline opens, the evaporation tank is pressurized, and the concentration hydraulic pressure is fed into the concentration tank.

What effects can we achieve

Our company's evaporation equipment can achieve a concentration ratio of 5-100 times under different water quality conditions. Evaporators have been widely used in various industries such as food industry, pharmaceutical industry, chemical industry, environmental protection, and energy due to their high efficiency, energy efficiency, strong adaptability, high degree of automation, environmental safety, and stable operation.

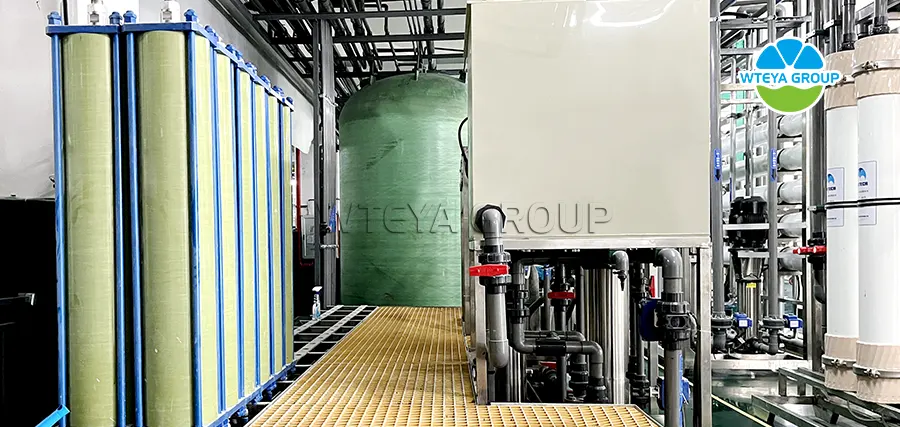

2. Membrane separation equipment: DTRO, STRTO, NF, etc.

Applied in which production process

The application of membrane separation technology in the mining and metallurgical industry is mainly reflected in the following aspects:

- Slurry concentration and pretreatment

Fine grained slurry concentration: Traditional concentration methods may be inefficient for slurry with small particle sizes after grinding. The use of ceramic membrane and other membrane separation technologies can efficiently concentrate the slurry, increase the slurry concentration to the required level for subsequent separation processes, and is particularly suitable for processing difficult to select fine ores in low-grade resource development.

Harmful element removal: Membrane separation technology can selectively remove harmful elements or associated elements, such as heavy metal ions, contained in the slurry. Through the selection of specific membrane materials and the regulation of operating conditions, the goal of purifying the slurry and improving resource utilization is achieved.

- Optimization of Hydrometallurgical Processes

Purification of Leaching Solution and Enrichment of Metal Ions: In the process of wet metallurgy, membrane separation technology can deeply purify the leaching solution, remove suspended solids, colloids, and some anionic impurities. At the same time, valuable metal ions (such as copper, nickel, zinc, gold, silver, etc.) can be concentrated and enriched through methods such as nanofiltration and reverse osmosis, reducing the load and cost of subsequent extraction, precipitation, or electrowinning processes.

Recycling of complexing agents, acids, bases and other reagents: The complexing agents, acids, bases and other reagents used in the leaching or precipitation process can be recycled and reused through membrane separation equipment, reducing chemical consumption, production costs, and minimizing environmental impact.

- Wastewater treatment and resource recovery

Heavy metal wastewater treatment: The heavy metal wastewater generated during the metallurgical process can be effectively intercepted by membrane separation technology (such as reverse osmosis, electrically driven membranes, etc.) to meet the discharge standards or further recover heavy metal resources.

Sulfuric acid and alkali recovery: In the wet metallurgical process, sulfuric acid and alkali are often used as leaching agents or reagents to adjust pH values. Membrane separation equipment can effectively recover sulfuric acid and alkali from waste liquid, achieve closed-loop management of acid-base balance, reduce the cost of purchasing new acid and alkali, and reduce waste discharge.

- Tailings and by-product treatment

Tailings slurry dewatering: The use of pressure filtration membranes or ceramic membranes for deep dewatering of tailings slurry can significantly reduce the volume of tailings storage, reduce land occupation, reduce potential environmental risks, and facilitate the subsequent reuse of valuable components in tailings.

Byproduct purification and value-added: For by-products generated in the wet metallurgical process, such as sulfides, sulfates, etc., membrane separation technology can be finely separated and purified to enhance the market value of by-products and achieve maximum utilization of resources.

Technical Principles

The process of selectively separating components in liquid or gas mixtures using special thin films. The main principle of this technology is based on the differences in the speed and ability of different components to penetrate the membrane, which may be determined by the properties of the components, the characteristics of the membrane, and factors such as the concentration difference, pressure gradient, potential gradient, or vapor partial pressure on both sides of the membrane. Membrane separation methods include microfiltration, ultrafiltration, nanofiltration, reverse osmosis, and electrodialysis, each of which is suitable for different separation needs. For example, microfiltration and ultrafiltration screen molecules or solutes of different sizes based on the pore size of the membrane; Reverse osmosis is the process of trapping solutes by allowing solvents to pass through a membrane at pressures higher than the osmotic pressure of the solution; Electrodialysis is the selective separation of ions from a solution using ion exchange membranes under the action of an electric field.

What effects can we achieve

The membrane separation process usually has the characteristics of low energy consumption and low operating temperature. Compared with traditional separation methods, it can significantly reduce energy consumption and greenhouse gas emissions. In addition, through resource recovery and wastewater reduction, energy demand and carbon footprint have been indirectly reduced. Membrane separation technology is not only used in the mining and metallurgical industry for slurry concentration, wet metallurgical process optimization, wastewater treatment and resource recovery, but also involves multiple links such as tailings treatment, environmental monitoring, energy conservation and emission reduction. It is of great significance for improving resource utilization, reducing production costs, reducing environmental pollution, and achieving green and sustainable development.

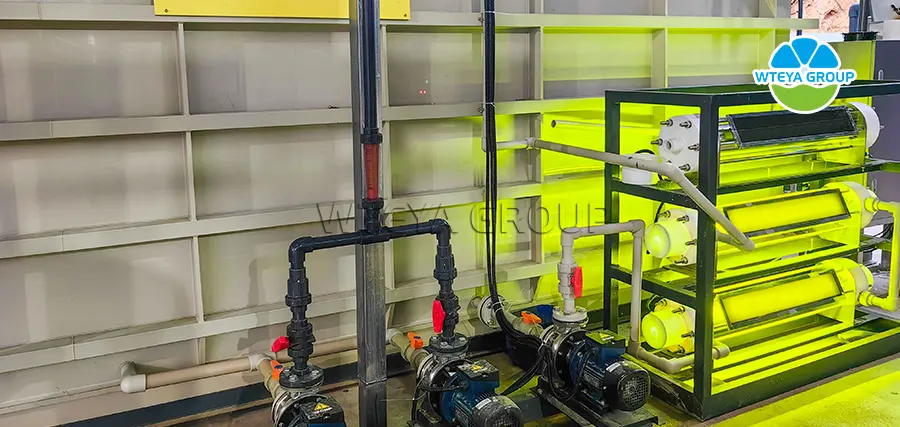

3. ECC catalytic oxidation equipment:

Applied in which production process

ECC catalytic oxidation equipment is mainly used for the removal of organic compounds in high salt feed liquids in the mining and metallurgical industry. It can also kill microorganisms in water to ensure the purity of the feed solution, providing assurance for the normal operation of the equipment.

Technical Principles

ECC catalytic oxidation technology is a new technology developed by our company, which uses catalysts to promote the oxidation reaction between organic pollutants and oxidants (such as oxygen, ozone, hydrogen peroxide, etc.) under specific conditions, generating harmless or low toxic final products, and achieving effective removal of pollutants. Different catalytic oxidation equipment adopts different oxidants, catalysts, and reaction conditions according to different application scenarios and processing objects to meet various practical needs.

What effects can we achieve

The removal efficiency of such products by the company for organic matter (CODcr) can reach below 80%, and some can exceed 95%. It can also greatly reduce the probability of foam occurrence in high temperature reaction kettle and evaporation equipment and the scaling of membrane system.

Get a free quote!

Let professionals help you choose

Our Customers And Services