1. Integrated pretreatment equipment

Applied in which production process

Integrated sewage treatment equipment plays a crucial role in the environmental protection industry, and its widespread application is mainly reflected in the following aspects:

- Urban domestic sewage treatment:

Residential communities: Integrated sewage treatment equipment can treat the daily sewage generated by residents in the community, including wastewater from kitchens, bathrooms, laundry rooms, etc., effectively removing organic matter, nitrogen and phosphorus nutrients, and pathogenic microorganisms, ensuring that the effluent quality meets the standard, reducing the pressure on urban sewage treatment plants, and avoiding untreated domestic sewage from being directly discharged into natural water bodies, causing eutrophication and environmental pollution.

Tourist attractions and resorts: For areas with high population density fluctuations such as scenic spots and resorts, integrated equipment can flexibly respond to changes in sewage volume, ensuring effective treatment of temporary or seasonal increases in sewage and protecting sensitive ecological environments.

- Rural and remote area sewage treatment:

Rural domestic sewage: Given the lack of comprehensive sewage treatment facilities in rural areas of China, integrated equipment is particularly suitable for decentralized treatment of domestic sewage from rural households and small communities due to its small footprint, convenient installation, and simple operation and maintenance. This improves the rural water environment and helps implement the rural revitalization strategy.

• Remote areas: For remote areas with inconvenient transportation and insufficient power supply, integrated sewage treatment equipment can use renewable energy sources such as solar and wind power to achieve off grid operation, solve local sewage treatment problems, and protect the water quality of water sources and ecologically fragile areas.

- Commercial and Public Service Facilities:

Hotels, restaurants, and shopping malls: The wastewater generated from commercial activities usually contains high concentrations of organic matter and oil. Integrated equipment can carry out targeted pretreatment and biochemical treatment, effectively removing pollutants and ensuring compliance with discharge regulations.

Schools, hospitals, and sanatoriums: The sewage generated in these places may contain special pollutants such as drug residues and pathogenic microorganisms in addition to conventional domestic sewage. Integrated equipment combined with disinfection units can achieve high standards of sewage treatment, prevent the spread of pathogenic microorganisms, and ensure public health safety.

- Industrial wastewater treatment:

Small and medium-sized enterprises: For industrial enterprises with small scale, small sewage discharge but complex types of pollutants, integrated sewage treatment equipment can be customized to treat specific industrial wastewater, such as wastewater from food processing, printing and dyeing, electroplating and other industries, achieving standard discharge or reuse.

Centralized treatment in industrial parks: An integrated sewage treatment station is established within the park to centrally treat industrial wastewater from various settled enterprises. Through optimization and integration, resource sharing is achieved, costs are reduced, and centralized supervision is facilitated to ensure overall discharge meets standards.

- Emergency sewage treatment:

Natural disaster response: After disasters such as floods and earthquakes occur, integrated equipment can be quickly deployed to handle the large amount of temporary domestic sewage generated in the disaster area, prevent secondary water environmental pollution, and ensure the safety and hygiene of drinking water for disaster victims.

Construction sites and temporary camps: During the construction period or field operation camps, integrated equipment can serve as temporary sewage treatment facilities to treat workers' domestic sewage, meet environmental protection regulations, and protect the surrounding environment.

- Ecological restoration projects:

Wetland restoration and protection: In wetland ecosystem restoration projects, integrated equipment can serve as pre-treatment facilities for artificial wetland systems, reducing the treatment burden on wetland plants, improving the treatment efficiency of the entire system, and ensuring the restoration of wetland ecological functions.

- Water resource reuse:

• Reuse of reclaimed water: After being treated by integrated equipment, the effluent can be used for non drinking water purposes such as flushing toilets, watering green spaces, and landscape replenishment after deep treatment, achieving rational utilization of water resources and alleviating water scarcity problems.

Technical Principles

This type of equipment mainly adopts primary, secondary, and tertiary treatment technologies such as natural sedimentation and coagulation sedimentation technology, filtration, centrifugal separation technology, and biochemical technology for sewage purification and treatment.

What effects can we achieve

We can achieve fully automated operation and unmanned operation of such devices, saving a lot of manpower; The removal efficiency of suspended solids (SS) can reach 80-95%, and the removal efficiency of organic matter can reach over 80%.

2. Evaporation equipment: such as MVR evaporation equipment, forced circulation equipment, low-temperature evaporation equipment, and multi effect evaporation equipment

Applied in which production process

Evaporation equipment is mainly used in the environmental protection industry for wastewater treatment, resource recovery, and environmental remediation, as follows:

- Wastewater treatment and zero discharge (ZLD)

High salt wastewater treatment: In industries such as chemical, pharmaceutical, printing and dyeing, electroplating, and coal chemical, a large amount of high salt wastewater is generated. Evaporation equipment (such as multi effect evaporators, MVR evaporators, TVR evaporators, etc.) can evaporate the moisture in wastewater to form concentrate and distilled water. Concentrated liquid can be further solidified for treatment or resource utilization, while distilled water can be reused in the production process or discharged to meet standards, achieving the reduction and resource utilization of wastewater and complying with increasingly strict environmental regulations.

Heavy metal wastewater treatment: For wastewater containing heavy metal ions, evaporation equipment can concentrate the heavy metal salts in it, so as to recover heavy metal resources through chemical precipitation, electrodeposition and other methods, reduce environmental pollution risks, and increase economic benefits.

- Resource recycling and by-product processing

Salt crystallization and recovery: In certain chemical processes or wastewater treatment, evaporation equipment can concentrate saline wastewater to saturation, and separate valuable salts such as sodium sulfate, sodium chloride, calcium chloride, etc. through cooling crystallization, achieving resource recovery.

Useful component recovery: Evaporation equipment can be used to recover valuable components from wastewater, such as amino acids, organic acids, alcohols, ketones, etc., separate them and return them to the production process, achieving resource recycling and reducing production costs.

- Energy conservation and emission reduction

Waste heat utilization: In the process of wastewater evaporation, the evaporation equipment can use internal waste heat, low-temperature steam, or condensate water as heat sources to achieve effective energy utilization and reduce overall energy consumption.

Reducing solid waste generation: Treating wastewater through evaporation equipment can greatly reduce the generation of solid waste (such as evaporation residue), lower the cost of solid waste disposal, and alleviate environmental pressure.

- Historical Heritage of Environmental Restoration and Governance

For high salt, high organic matter, and heavy metal waste liquids left over during the retirement or renovation process of industrial facilities, evaporation equipment can be used as one of the treatment technologies. Through evaporation and concentration of waste liquids, safe disposal or resource recovery of waste liquids can be achieved, helping enterprises to restore the environment.

- Special chemical production

In the production of certain specialized chemicals, such as preparing high-purity anhydrous salts and special crystalline salts, evaporation equipment is one of the key equipment. By precisely controlling evaporation and crystallization conditions, products that meet specific purity and crystal requirements are produced.

Technical Principles

- MVR evaporator equipment: The MVR evaporator reuses the energy of the secondary steam it generates, thereby reducing the demand for external energy. The working process of MVR is to compress the low-temperature steam through a compressor, increase the temperature and pressure, increase the enthalpy, and then enter the heat exchanger for condensation to fully utilize the latent heat of the steam. Except for start-up, the entire evaporation process does not require the generation of steam. The secondary steam coming out of the evaporator is compressed by the compressor, which increases pressure and temperature, enthalpy, and then sent to the heating chamber of the evaporator for use as heating steam, maintaining the boiling state of the material liquid.

- Forced circulation evaporation equipment: The circulation of solution inside the equipment mainly relies on the forced flow generated by external force. The cycle speed can generally reach 1.5-3.5 meters per second. High heat transfer efficiency and production capacity. The raw material liquid is pumped from bottom to top by a circulating pump and flows inward and upward along the heating chamber tube. After entering the evaporation chamber, the mixture of steam and liquid foam separates, and the steam is discharged from the upper part. The fluid is blocked and falls down. It is sucked in by the circulation pump at the conical bottom and then enters the heating tube to continue circulation. It has a high heat transfer coefficient, resistance to salt precipitation, anti scaling, strong adaptability, and is easy to clean. Suitable for evaporative concentration in chemical, food, pharmaceutical, environmental engineering, waste liquid evaporation and recovery industries with scaling, crystallinity, thermal sensitivity (low temperature), high concentration, high viscosity, and insoluble solids.

- Low temperature evaporation equipment: Low temperature evaporation refers to an evaporation process that operates at temperatures generally between 35-50 ℃. After the raw water bucket reaches the middle liquid level, the water pump operates to generate a vacuum, and the evaporator automatically receives water. The compressor operates to generate heat to heat the wastewater in the evaporation tank. Under vacuum, the wastewater temperature rises to around 30 ℃, and the wastewater begins to evaporate. Preheating is completed. The evaporation temperature is set to 35-40 ℃, and the compressor compresses the refrigerant to generate heat. While the water evaporates rapidly, the refrigerant absorbs heat and cools through the expansion valve after gasification. The vapor rises and liquefies with the cold liquid, entering the water storage tank. The refrigerant absorbs heat and compresses it through the compressor to heat up the wastewater. If there are bubbles rising during the evaporation process, the sensor will detect it and automatically add defoamer. After one cycle is completed, the concentrated solution will be discharged (the time of one cycle can be set). After one evaporation cycle is completed, the compression pump stops working, the pneumatic valve of the concentration liquid pipeline opens, the evaporation tank is pressurized, and the concentration hydraulic pressure is fed into the concentration tank.

What effects can we achieve

Our company's evaporation equipment can achieve a concentration ratio of 5-100 times under different water quality conditions. Evaporators have been widely used in various industries such as food industry, pharmaceutical industry, chemical industry, environmental protection, and energy due to their high efficiency, energy efficiency, strong adaptability, high degree of automation, environmental safety, and stable operation.

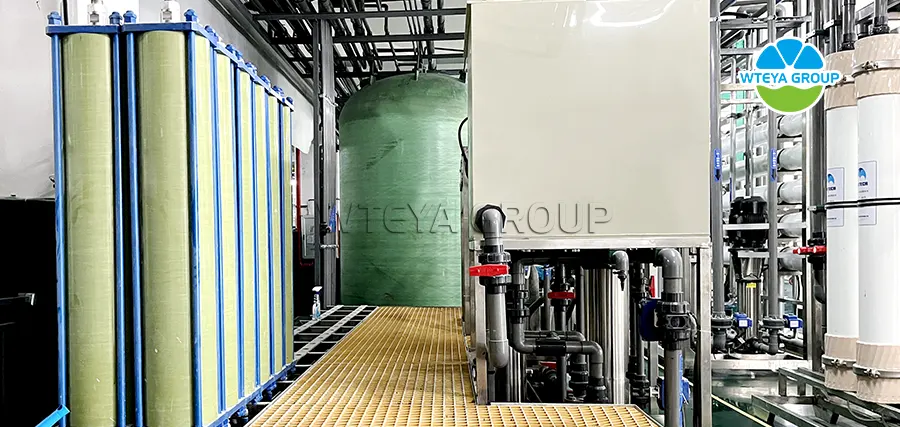

3. Membrane separation equipment: DTRO, STRTO, NF, etc

Applied in which production process

Membrane separation equipment has important application value in the production and processing industry of battery positive electrode materials, mainly reflected in the following aspects:

- Raw material purification and purification

Ion separation and concentration: Membrane separation technology, especially nanofiltration (NF) and reverse osmosis (RO) membranes, can be used for deep purification of lithium salt solutions required for the production of positive electrode materials (such as lithium carbonate, lithium sulfate, etc.), effectively removing harmful ions, trace metal impurities, and organic pollutants, improving the purity of lithium salt solutions, and providing high-purity raw materials for the subsequent synthesis of high-quality positive electrode materials.

- Solvent recovery and recycling

In the preparation process of certain positive electrode materials, such as solvothermal method, organic solvents are used. Membrane separation equipment can separate and recover wastewater or waste liquid containing organic solvents, reduce solvent consumption, reduce waste generation, and reduce environmental pollution risks.

- Separation of intermediates and by-products

Precursor washing and grading: In the synthesis stage of precursor materials for positive electrodes, such as co precipitated hydroxides or carbonates, they can be washed and graded through microfiltration (MF) or ultrafiltration (UF) membranes to remove small particle impurities, improve the uniformity and purity of precursor particle size distribution.

Desalination of by-products: In some wet processes, by-product solutions containing high concentrations of inorganic salts are produced. Membrane separation technology can help remove these salts, allowing by-products to be further utilized as resources or safely disposed of.

- Wastewater treatment and recovery

Wastewater reuse: The wastewater generated during the production process of battery positive electrode materials often contains high concentrations of metal ions and other harmful substances. Membrane separation equipment, such as reverse osmosis or nanofiltration membranes, can be used for deep treatment of these wastewater, achieving water resource reuse, reducing fresh water consumption and wastewater discharge.

Heavy metal recovery: For wastewater containing valuable metal ions (such as cobalt, nickel, manganese, etc.), selective interception and recovery can be achieved through special membrane separation technologies such as ion exchange membranes or chelation membranes, achieving the dual goals of resource recovery and environmental protection.

Technical Principles

The process of selectively separating components in liquid or gas mixtures using special thin films. The main principle of this technology is based on the differences in the speed and ability of different components to penetrate the membrane, which may be determined by the properties of the components, the characteristics of the membrane, and factors such as the concentration difference, pressure gradient, potential gradient, or vapor partial pressure on both sides of the membrane. Membrane separation methods include microfiltration, ultrafiltration, nanofiltration, reverse osmosis, and electrodialysis, each of which is suitable for different separation needs. For example, microfiltration and ultrafiltration screen molecules or solutes of different sizes based on the pore size of the membrane; Reverse osmosis is the process of trapping solutes by allowing solvents to pass through a membrane at pressures higher than the osmotic pressure of the solution; Electrodialysis is the selective separation of ions from a solution using ion exchange membranes under the action of an electric field.

What effects can we achieve

Membrane separation equipment can be integrated into continuous and automated production lines to achieve continuous separation, purification, and recovery of materials, which helps to improve production efficiency, reduce quality fluctuations between batches, reduce energy consumption, and conform to the green and efficient production concept of modern battery manufacturing industry.

The application of membrane separation equipment in the production and processing industry of battery positive electrode materials is extensive and important, mainly reflected in raw material purification, intermediate and by-product separation, wastewater treatment and recovery, gas treatment, and promoting continuous production process optimization. It plays a significant role in improving the quality of positive electrode materials, reducing costs, energy conservation and emission reduction, and achieving sustainable production. With the continuous development and improvement of membrane separation technology, its application prospects in the battery material industry will be even broader.

4. ECC catalytic oxidation equipment:

Applied in which production process

Catalytic oxidation equipment is mainly used in various fields in the water treatment industry, including industrial wastewater treatment, municipal wastewater treatment and upgrading, groundwater and surface water pollution control, etc. It is of great significance to improve wastewater treatment efficiency, achieve wastewater resource utilization, and protect water environment quality. With the development of catalytic materials science, equipment design, and process optimization technology, the application of catalytic oxidation equipment in the water treatment industry will be more extensive and in-depth. Specifically, as follows:

- Industrial wastewater treatment

Chemical wastewater: The wastewater generated during the chemical production process often contains complex and difficult to degrade organic compounds, such as aromatic compounds, polycyclic aromatic hydrocarbons, phenols, dye intermediates, etc. Catalytic oxidation equipment (such as electrocatalytic oxidation, ozone catalytic oxidation, Fenton oxidation, etc.) generates strong oxidizing free radicals (such as · OH) to react with these organic pollutants, decompose them into small molecules or mineralize them into carbon dioxide and water, reduce the chemical oxygen demand (COD) and biological toxicity of wastewater, improve the biodegradability of wastewater, and create conditions for subsequent biological treatment or directly achieve standard discharge of wastewater.

Pharmaceutical wastewater: Pharmaceutical wastewater usually contains difficult to degrade organic compounds such as antibiotics, hormones, synthetic drug intermediates, and may contain biological inhibitory substances. Catalytic oxidation technology can efficiently destroy these organic pollutants, reduce their inhibitory effect on biological treatment systems, and remove antibiotic residues from wastewater to prevent their accumulation in the environment, posing a threat to the ecological environment and human health.

Petrochemical wastewater: Petrochemical wastewater contains complex pollutants such as petroleum hydrocarbons, polycyclic aromatic hydrocarbons, sulfides, etc. Catalytic oxidation equipment converts these pollutants into easily biodegradable small molecules or harmless substances through catalytic oxidation, achieving effective pretreatment of wastewater and reducing the load on subsequent biological treatment systems.

Printing and dyeing wastewater: Printing and dyeing wastewater contains a large amount of organic substances such as dyes and additives, with deep colors, high chromaticity, and poor biodegradability. Catalytic oxidation equipment can effectively remove colored organic compounds from wastewater, significantly reduce chromaticity, and improve the biodegradability of wastewater, providing good conditions for subsequent biochemical or deep treatment.

- Municipal sewage treatment and upgrading

Secondary biochemical effluent deep treatment: For municipal sewage treatment plant effluent that has undergone biochemical treatment but still cannot meet discharge standards or reuse requirements, catalytic oxidation equipment can be used as a deep treatment process to further remove residual organic matter, ammonia nitrogen and other pollutants in the water, improve effluent quality, and achieve standard discharge or reuse of reclaimed water.

Upgrading and renovation of sewage treatment plants: In the existing sewage treatment plant upgrading and renovation projects, catalytic oxidation equipment can be used as an enhanced treatment unit to supplement or replace the original process, in order to cope with increasingly strict discharge standards and water quality requirements, and improve the overall treatment efficiency of the sewage treatment plant.

- Groundwater and surface water pollution control

Organic pollution remediation of groundwater: For groundwater contaminated with organic matter, especially groundwater sources containing persistent organic pollutants (POPs), catalytic oxidation equipment can be applied in in-situ or ex situ groundwater remediation projects. Through catalytic oxidation technology, difficult to degrade organic pollutants in groundwater are destroyed, water quality is improved, and groundwater resources are protected.

Restoration of surface water bodies such as lakes and rivers: In surface water treatment projects contaminated with organic matter, catalytic oxidation equipment can serve as shore treatment facilities or mobile treatment platforms to quickly and effectively treat the extracted polluted water, reduce the concentration of organic pollutants, and promote ecological restoration of water bodies.

Technical Principles

ECC catalytic oxidation technology is a new technology developed by our company, which uses catalysts to promote the oxidation reaction between organic pollutants and oxidants (such as oxygen, ozone, hydrogen peroxide, etc.) under specific conditions, generating harmless or low toxic final products, and achieving effective removal of pollutants. Different catalytic oxidation equipment adopts different oxidants, catalysts, and reaction conditions according to different application scenarios and processing objects to meet various practical needs.

What effects can we achieve

The removal efficiency of such products by the company for organic matter (CODcr) can reach below 80%, and some can exceed 95%. It can also greatly reduce the probability of foam occurrence in high temperature reaction kettle and evaporation equipment and the scaling of membrane system.

Get a free quote!

Let professionals help you choose

Our Customers And Services