Recently, with the increasing strictness of environmental requirements and the growth of industrial wastewater treatment needs, the

MVR evaporation system has become a key technological breakthrough in the field of high-salinity wastewater treatment, thanks to its high efficiency and energy-saving characteristics. By optimizing the design and operation mode of MVR evaporators, this technology significantly reduces energy consumption while improving wastewater treatment efficiency, providing sustainable solutions for industries such as chemical, petroleum, pharmaceutical, food, manufacturing, electroplating, and new energy.

MVR equipment (Mechanical Vapor Recompression evaporation system) recycles the thermal energy of secondary steam, converting electrical energy into thermal energy for reuse. Compared with traditional evaporation systems, it can save more than 60% energy. The latest generation of MVR evaporators uses high-efficiency compressors and intelligent control systems to further reduce energy consumption, while adapting to the treatment needs of higher-concentration high-salinity wastewater, effectively solving the problems of high operation costs and low efficiency in traditional evaporation technologies.

In industries such as chemical, petroleum, manufacturing, and electroplating, the treatment of high-salinity wastewater has always been a major challenge. The MVR evaporation system uses low-temperature evaporation technology, which not only avoids damage to equipment caused by salt scaling but also concentrates and crystallizes the salt in the wastewater for resource recovery. After a chemical enterprise applied this technology, its wastewater treatment efficiency increased by 30%, saving over one million yuan in energy costs annually.

WTEYA stated that with the continuous optimization and large-scale application of MVR equipment, its advantages in the field of high-difficulty wastewater treatment will be further highlighted. In the future, combined with IoT and big data technologies, the MVR evaporation system is expected to achieve intelligent operation, providing stronger support for the goal of zero discharge of industrial wastewater.

Currently, WTEYA has accelerated the R&D and production layout of MVR evaporators, promoting the industrialization of energy-saving technologies to support the green manufacturing transformation. The popularization of this technology will bring new breakthroughs to global high-salinity wastewater treatment.

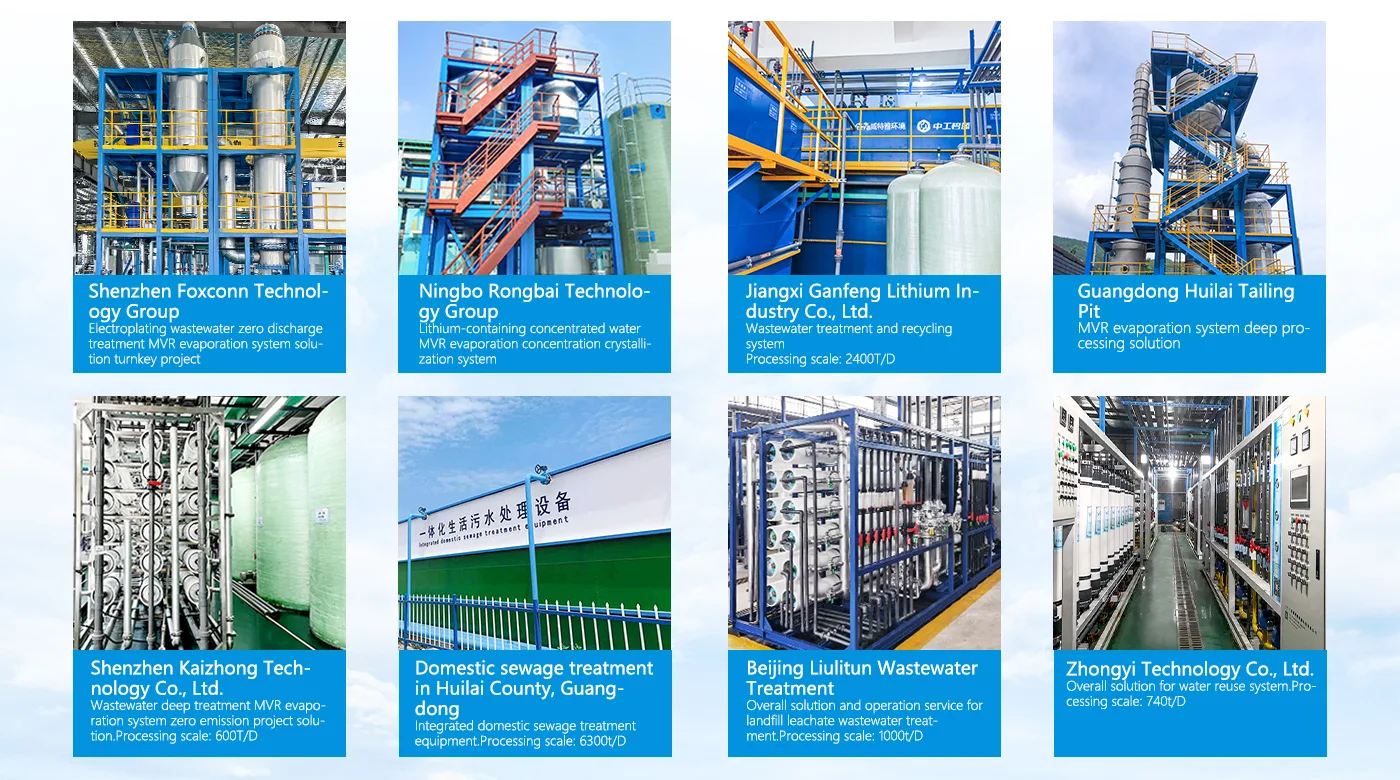

WTEYA is your trusted brand partner. With more than a decade of experience, we have provided efficient and reliable evaporation and crystallization treatment solutions for many renowned global enterprises, successfully implementing projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over 100 project cases, winning wide trust and praise from customers. We support OEM & ODM customization to meet your unique needs for tailored solutions.

Welcome to join us. As a 16-year-old brand, WTEYA offers you various preferential policies, professional training and guidance, and comprehensive technical support—worthy of your trust!