WTEYA Small-Scale Sewage Treatment Equipment | Community/Factory/Scenic Spot Sewage Meets Standards with One Click!

Release Time:

2025-10-20 09:43

💧 WTEYA Small-Scale Sewage Treatment Equipment | Community/Factory/Scenic Spot Sewage Meets Standards with One Click!

😰 Still held back by "sewage treatment"?

Is the treatment of high-salt wastewater in factories inefficient and costly? Is the sewage discharge from community homestays failing to meet standards, risking environmental fines? Do sewage volumes surge during peak seasons at tourist attractions, overwhelming treatment facilities? Don’t let "sewage problems" become an obstacle to development! The WTEYA Small-Scale Sewage Treatment Equipment, centered on "high efficiency, compactness + intelligence and convenience", provides tailored sewage solutions for communities, factories, and scenic spots. It makes the treatment process "time-saving, labor-saving, and cost-saving", achieving a win-win for environmental protection and efficiency!

✨ Three Core Advantages to Address Key Pain Points

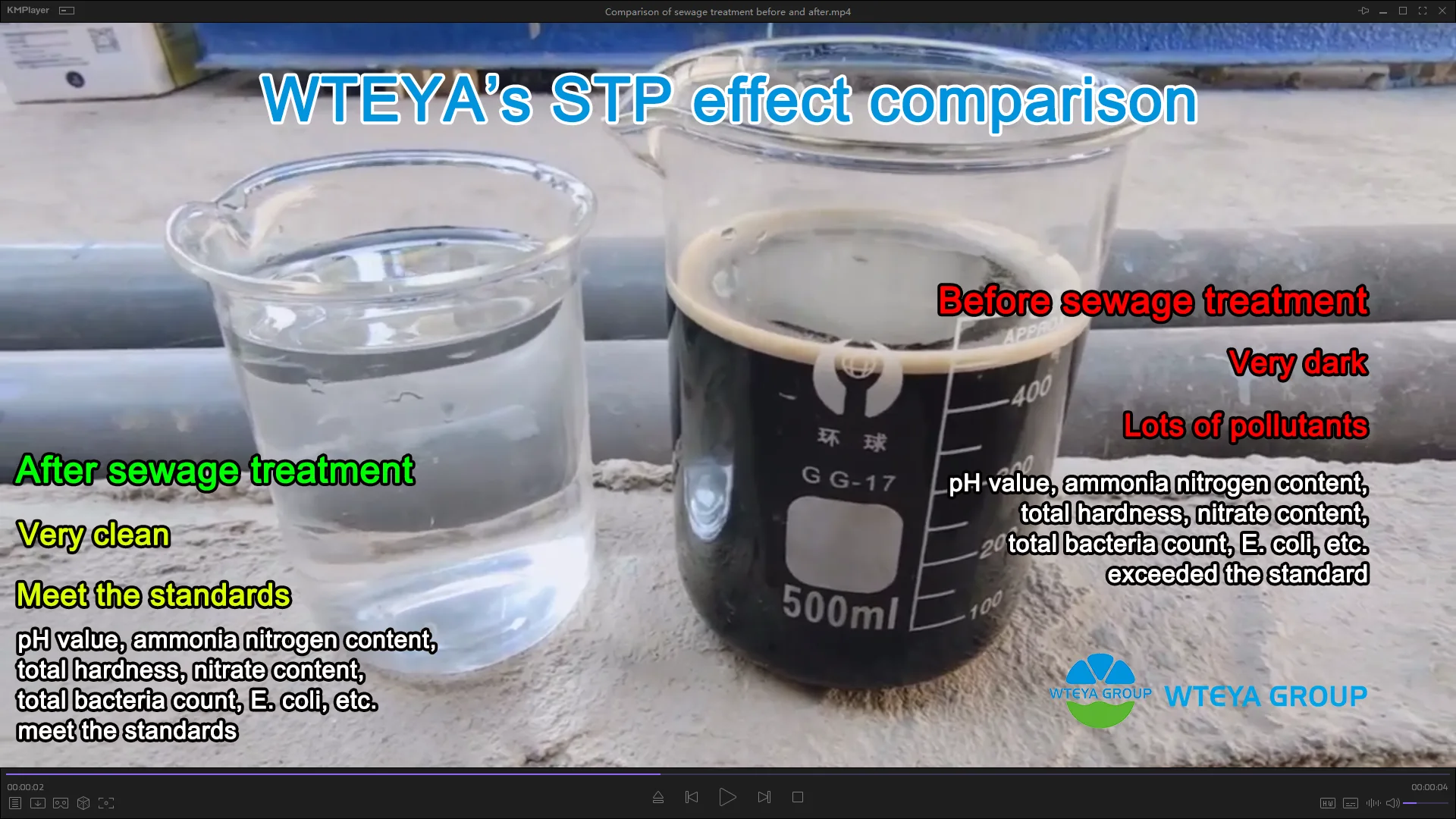

✅ High Efficiency & Speed, Water Quality Meets Standards in Seconds

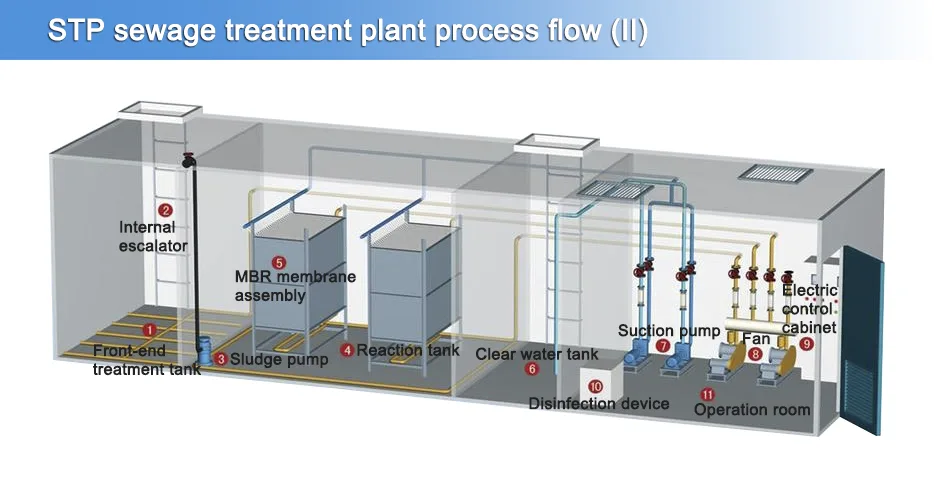

Integrated with MBR membrane bioreactor + high-efficiency sedimentation technology, it achieves a COD removal rate of >95% and an ammonia nitrogen removal rate of >90%. Indicators such as SS and TP fully meet standards! Whether it is high-salt factory wastewater (salt content ≤5000mg/L), domestic sewage in communities, or catering wastewater in scenic spots, it can stably treat the water to meet discharge standards, ensuring easy passage of environmental acceptance inspections!

Ready to use, no waiting: Modular design with 90% of components prefabricated in the factory. On-site installation is fast, and the equipment meets standards as soon as it is turned on—saying goodbye to the nightmare of traditional civil engineering treatment plants with "long construction cycles and complicated commissioning"!

✅ Compact & Flexible, "Zero Waste" of Space

Covers an area equivalent to only 2 parking spaces. It can be flexibly combined according to the treatment capacity (5-500m³/day) and can be placed in community corners, factory open spaces, or scenic spot green belts, perfectly adapting to narrow sites. Compared with traditional treatment facilities, it saves more than 40% of land costs!

Fully automated operation, unattended: Equipped with a PLC intelligent control system + remote monitoring function, it automatically adjusts aeration volume and chemical dosage, and triggers automatic fault alarms. Operating data can be viewed online, reducing labor costs by 60% directly!

✅ Low-Cost Operation, More Savings & Peace of Mind

Ultra-low energy consumption: Adopts an energy-saving aeration system + sludge reduction technology, reducing operating costs by 30% compared with the traditional activated sludge process;

Direct sales from the original factory, full cost-effectiveness: Lean manufacturing in a 30,000㎡ intelligent workshop, eliminating middleman markups and ensuring reliable after-sales service!

🏭 Suitable for All Scenarios, Applicable to Communities/Factories/Scenic Spots

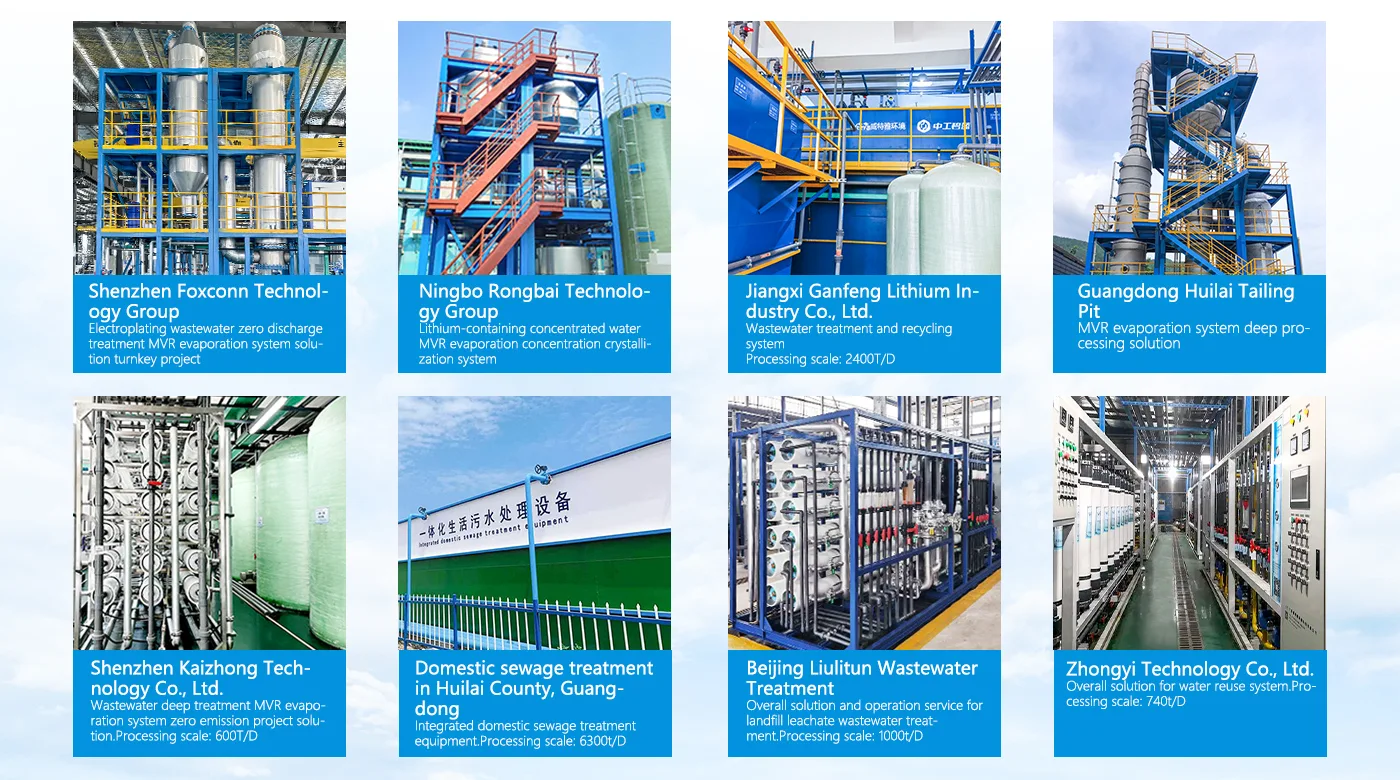

- Communities/Rural Homestays: Treats domestic sewage and catering wastewater, enabling reclaimed water reuse (for irrigation, toilet flushing) to build a "zero-discharge" green community;

- Small & Medium-Sized Factories: Treats electroplating wastewater, food processing wastewater, and high-salt wastewater to meet discharge standards or realize resource recycling, avoiding environmental penalties;

- Tourist Attractions/Campsites: Copes with peak passenger flow during peak seasons, quickly treats domestic sewage and toilet wastewater from tourists, and protects the ecological environment of scenic spots.

📣 Direct Sales from Factory, Global Agency Recruitment in Progress!

Whether you are a community property manager, a factory director, or an environmental engineering company, WTEYA can provide customized solutions! Contact us now to get free sewage treatment plan design and make sewage treatment "simpler"!

📱 WhatsApp: +86-1800 2840 855

✉ Email: info@wteya.com

🌐 Website: www.vteya.com

Front page of Cross

Next go-to page

Related information

WTEYA Landfill Leachate Treatment Equipment, with the core technology of "Evaporator + MVR + Membrane Combination Process", turns "toxic water" into "clean water" and truly achieves "full-quantity treatment and zero liquid discharge"!

Our Jordanian client once again raved about the WTEYA evaporation system, exceeding expectations!

The WTEYA evaporation system efficiently treats landfill leachate and high-salinity wastewater. It operates stably and is energy-efficient, making it a true "helper" for water treatment!

WTEYA: Bringing Life-Changing Water to the UAE's Desert Oasis!

WTEYA has developed solar-powered water treatment and desalination technology. Leveraging the UAE's abundant solar energy, it addresses water scarcity and provides communities with clean, safe drinking water.

The WTEYA Small-Scale Sewage Treatment Equipment, centered on "high efficiency, compactness + intelligence and convenience", provides tailored sewage solutions for communities, factories, and scenic spots.

🌊 WTEYA Makes a Splendid Debut at WATERTECH CHINA BEIJING!

WTEYA's Four Star Products: Seawater desalination systems convert seawater into fresh water efficiently ; water treatment plants are highly efficient and convenient ; evaporators combined with crystallization technology recover valuable resources ; and compact, high-efficiency sewage treatment plants support green upgrading !

WTEYA Evaporation and Crystallization Equipment achieves "concentration & volume reduction + resource recovery" of industrial waste liquids in one step, truly realizing "no wastewater leaving the factory, and value reuse"!